End-to-End System Development We build complete solutions: embedded systems, cloud infrastructure, and everything in between.

Custom Robotics & Automation

Industrial robotic arms, AGVs, pick-and-place systems with vision integration. ROS2, motion planning, real-time control loops.

IoT Network Architecture

Multi-node sensor networks, edge computing gateways, MQTT/CoAP protocols. LoRaWAN, Zigbee, cellular connectivity with cloud sync.

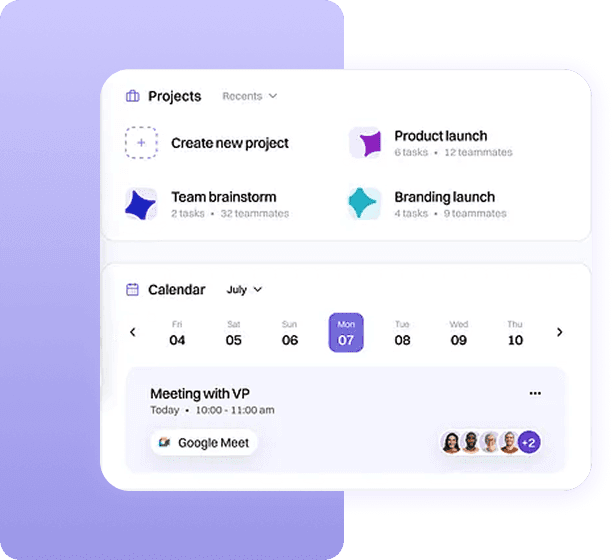

Full-Stack Engineering

Firmware (C/C++, Rust), backend APIs (Node.js, Python, Go), real-time dashboards (React, WebSockets), database optimization.

Technical Expertise Across Hardware, Software, and Cloud Platforms

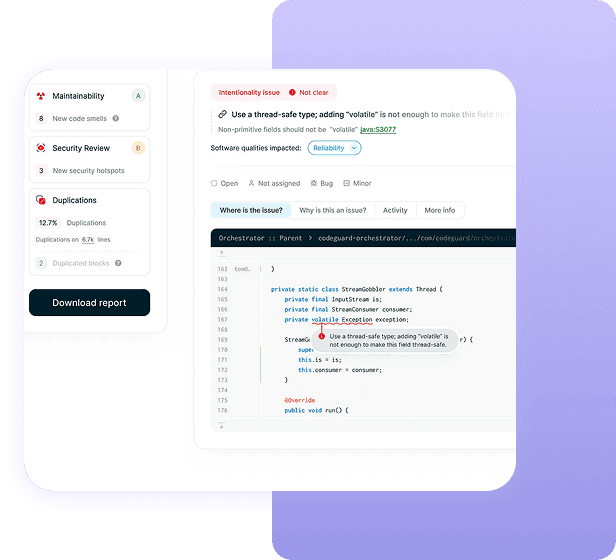

Embedded Systems Development

ESP32, STM32, Raspberry Pi integration. Real-time OS, low-power optimization, sensor fusion algorithms.

Industrial Automation

PLC programming, SCADA integration, process control systems. OPC-UA, Modbus, industrial protocols.

Computer Vision & AI

Object detection, quality inspection, pose estimation. TensorFlow, PyTorch, edge AI deployment.

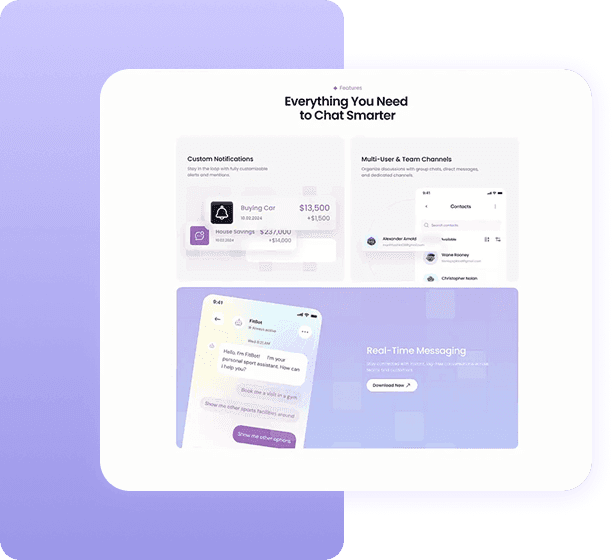

Cloud & Edge Computing

AWS IoT, Azure IoT Hub, Google Cloud IoT. Real-time data pipelines, edge analytics, OTA updates.

Mechanical & Electrical Design

CAD design, PCB layout, enclosure design. Motor control, power management, thermal analysis.

System Integration & Testing

Hardware-in-loop testing, CI/CD pipelines, production validation. Documentation, training, ongoing support.

Sensor network deployment

Robotic arm control

SCADA integration

Computer vision QA

Cloud data pipeline

Predictive maintenance

Custom PCB design

Edge AI deployment

PLC programming

Digital twin systems

LoRaWAN network

Real-time telemetry

Motion planning

Industrial HMI

IoT Sensor Networks & Data Infrastructure

Deploy multi-node wireless sensor arrays with edge processing. Real-time telemetry, predictive maintenance algorithms, cloud dashboards. Custom hardware + firmware + backend APIs.

View Technical SpecsRobotic Automation Systems

Custom robotic arms, conveyor systems, pick-and-place machines. Vision-guided manipulation, path planning, safety interlocks. Full mechanical design, control software, HMI development.

View Case Studies

Process Monitoring & Control

SCADA integration, PLC programming, industrial HMI. Real-time process visualization, alarm management, historical data logging. OPC-UA, Modbus TCP, proprietary protocol reverse engineering.

Schedule ConsultationConnect Everything: Legacy Systems, Modern Cloud, Custom Hardware

Discuss Your Project

Copyright © Vega IOT. All Rights Reserved by Vega IOT